Call us 9:00am - 6:00pm

09130014726

Monday to Saturday

9:00am - 6:00pm

E-mail us

fibreguard@brllp.in

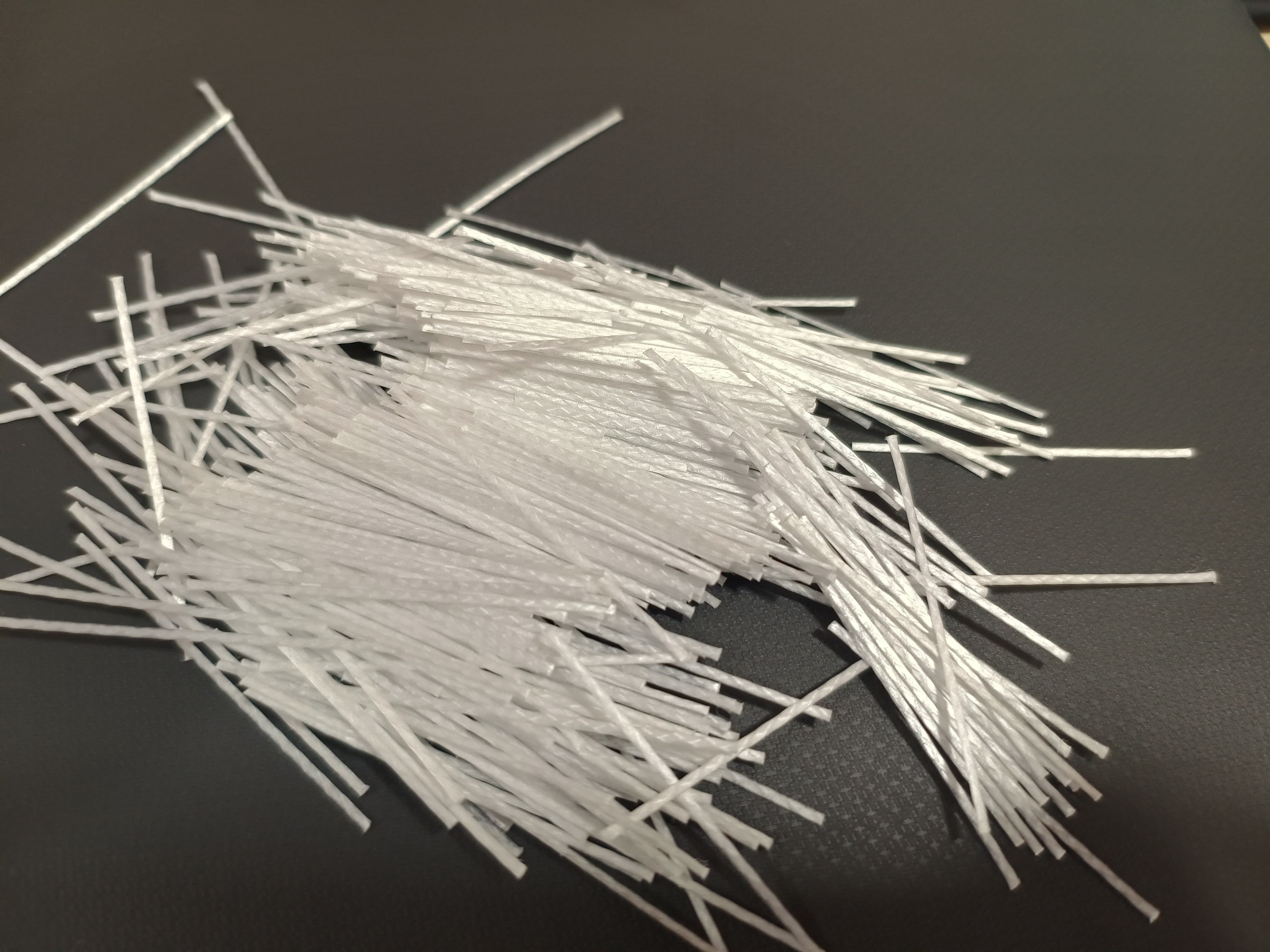

Fibre Tuff

Bajaj FibreTuff is a macro synthetic polypropylene fibre designed to provide superior reinforcement for concrete structures. Specially engineered for heavy-duty applications, it enhances the post-cracking capacity of concrete, making it an ideal replacement for steel and steel fibres. FibreTuff is widely used in a variety of applications, including ground-supported slabs, sprayed concrete (shotcrete), precast concrete units, and tunnel linings, both for temporary and permanent ground support. It is manufactured in compliance with BS EN 14889, ensuring it meets the highest standards for performance and durability in concrete reinforcement.

Macro synthetic fibre reinforced concrete (MSFRC) has become a widely adopted material in the construction industry, particularly in tunnel applications. Unlike traditional steel reinforcement, FibreTuff fibres are not susceptible to corrosion, making them a more durable and reliable solution in aggressive exposure conditions. These fibres are easy to pump and apply, reducing wear and tear on equipment and offering significant cost savings by eliminating the need for traditional steel reinforcement. With its corrosion-free nature and ease of application, FibreTuff ensures long-lasting performance without the risk of embrittlement or performance loss over time.

Why Choose Bajaj Fibre Tuff?

- Superior Durability

- Corrosion-Free

- Easy to Apply

- Cost-Effective

Provides enhanced durability, especially in harsh environments where traditional reinforcement may corrode.

Unlike steel reinforcement, Fibre Tuff is immune to corrosion, ensuring long-lasting performance without degradation.

Simplifies application and reduces wear on equipment, making it a more efficient solution compared to steel fibres or rebar.

Reduces overall material and labor costs by eliminating the need for traditional steel reinforcement methods.

Strength

Improves concrete’s overall strength and enhances its resistance to cracking.

Durability

Boosts durability, ensuring concrete withstands extreme environmental conditions.

Crack Control

Minimizes shrinkage and cracking during the initial curing phase for better stability.

Stability

Corrosion-resistant and chemically stable, ensuring reliable performance over time.

Applications

Tunnel Construction

Ideal for reinforcing tunnel linings, providing crack control and enhancing durability under high pressure.

Precast Structures

Enhances the strength and longevity of precast concrete units, ensuring consistent quality and performance.

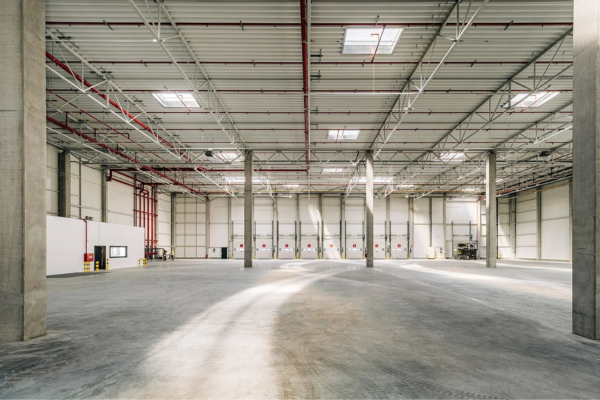

Industrial Flooring

Strengthens industrial flooring, improving impact resistance and reducing cracking under heavy loads.

Marine Structures

Offers superior protection against corrosion and environmental stressors in marine and coastal concrete applications.

Runways & Flooring

Strengthens runways and flooring, offering increased resistance to cracking, wear, and environmental stresses.

Learn more from our FAQ

What is FibreTuff and how does it work?

FibreTuff is a macro synthetic polypropylene fibre designed to enhance the post-cracking capacity of concrete. It is used as a replacement for steel fibres in various applications like slabs, shotcrete, precast units, and tunnel linings, providing superior strength and crack resistance.

How does FibreTuff improve the durability of concrete?

Can FibreTuff be used in tunnel construction?

Is FibreTuff easy to apply and handle?

Request a Quote

Fill all information details to consult with us to get sevices from us

Get in touch

Experience a true partnership where collaboration leads to exceptional outcomes and a final product that exceeds expectations.